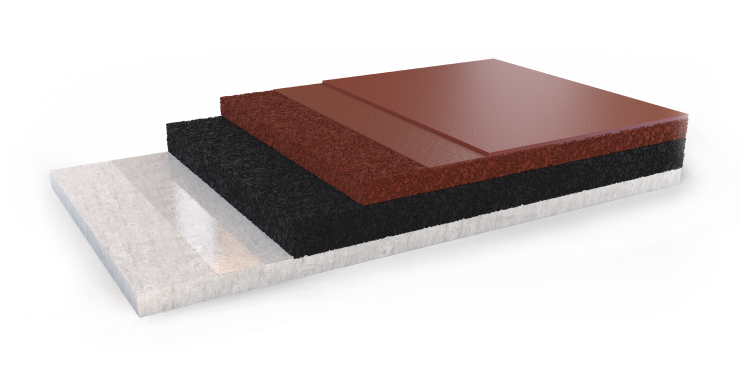

Synthetic outdoor system for running tracks. It is applied on fine asphalt or smooth, waterproof concrete, without rising humidity issues, beginning with the first layer (base layer) mixed at site, which consists of RECYCLED RUBBER 858 and the polyurethane binder POLAPLAST P13. Second layer (sealing layer) is the colored polyurethane sealing material POLAPLAST P22 on top of the cushion mixture, and third layer (surface layer) the full-PU colored polyurethane material POLAPLAST P20, before broadcasting EPDM granules on top to finish it off. Priming with POLAPLAST P10 precedes the application.

Certified system by WORLD ATHLETICS (former I.A.A.F).

Steps :

1. POLAPLAST P10 - Polyurethane primer. Applied by airless sprayer or brush.

2. Mixture of POLAPLAST P13 and RECYCLED RUBBER 858. Applied by paving machine.

3. POLAPLAST P22 - Colored polyurethane sealing layer. Applied by flat trowel.

4. POLAPLAST P20 - Colored, polyurethane full-PU, self-leveling surface layer. Applied by V-notch trowel and the parallel use of spiked roller.

5. Broadcasting EPDM granules in granulometry 1-3mm.