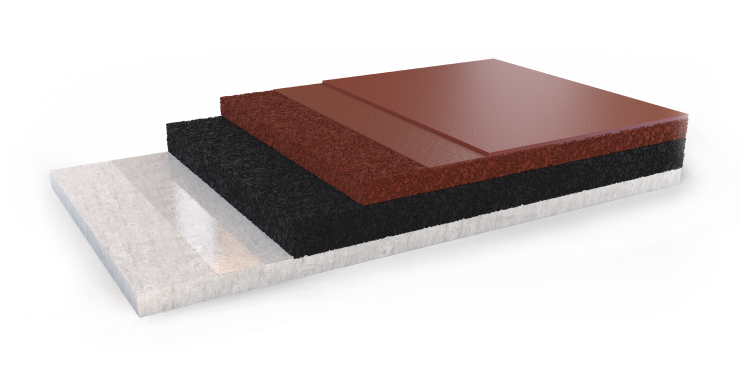

Synthetic outdoor system for running tracks in stadiums in total thickness of 15mm.

It is applied on fine asphalt or smooth, waterproof concrete, without rising humidity issues. After laying a PU primer for adhesion, follows the first layer (base layer), which consists of the FULL-PU colored polyurethane coating POLAPLAST P28 and RECYCLED RUBBER 858 broadcasted on top (fresh-on-fresh), a second layer comprising again the FULL-PU colored polyurethane coating POLAPLAST P28 laid on the surface and RECYCLED RUBBER 858 broadcasted on top (fresh-on-fresh) and the third layer (surface layer) is the full-PU colored polyurethane coating POLAPLAST P28 laid on the surface and EPDM granules broadcasted on top to finish it off (fresh-on-fresh).

Certified system by WORLD ATHLETICS.