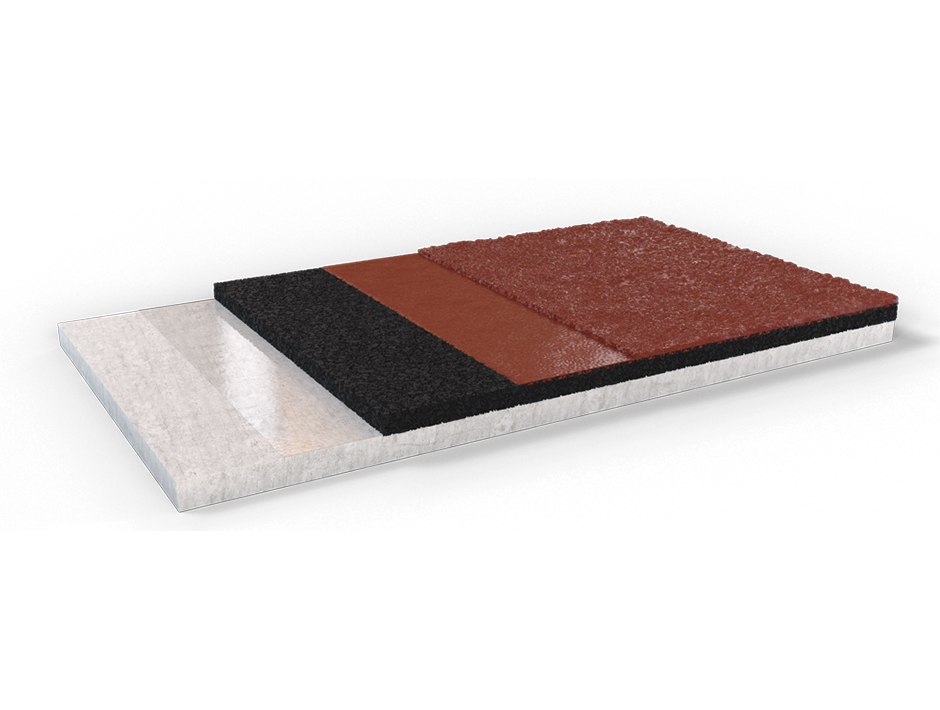

Synthetic outdoor system for running tracks. It is applied on fine asphalt or smooth, waterproof concrete, without rising humidity issues. Consists of a first base layer mixed at site, mixture of RECYCLED RUBBER 858 SBR granules and the polyurethane binder POLAPLAST P13, then a second layer (sealing layer), a polyurethane pore filler, POLYSPORT STUCCO 1050 and then a third layer, spray coat, is applied at site which consists of EPDM 856 (0.5-1.5mm) and the spraycoat, colored polyurethane binder POLAPLAST P12. Priming with POLAPLAST P10 precedes the application.

Steps:

1. POLAPLAST P10 - Polyurethane primer. Applied by airless sprayer or brush.

2. Mixture of POLAPLAST P13 and RECYCLED RUBBER 858 SBR granules. Applied by paving machine.

3. POLYSPORT STUCCO 1050 - Polyurethane, elastic, two-component pore filler. Used for sealing porous prefabricated subfloor of sports floorings such as ISOPOL 854 or wet-pour cushion shock-pads. Applied by flat trowel.

4. Mixture of POLAPLAST P12 and EPDM 856. Applied by spraying machine in two crossings.