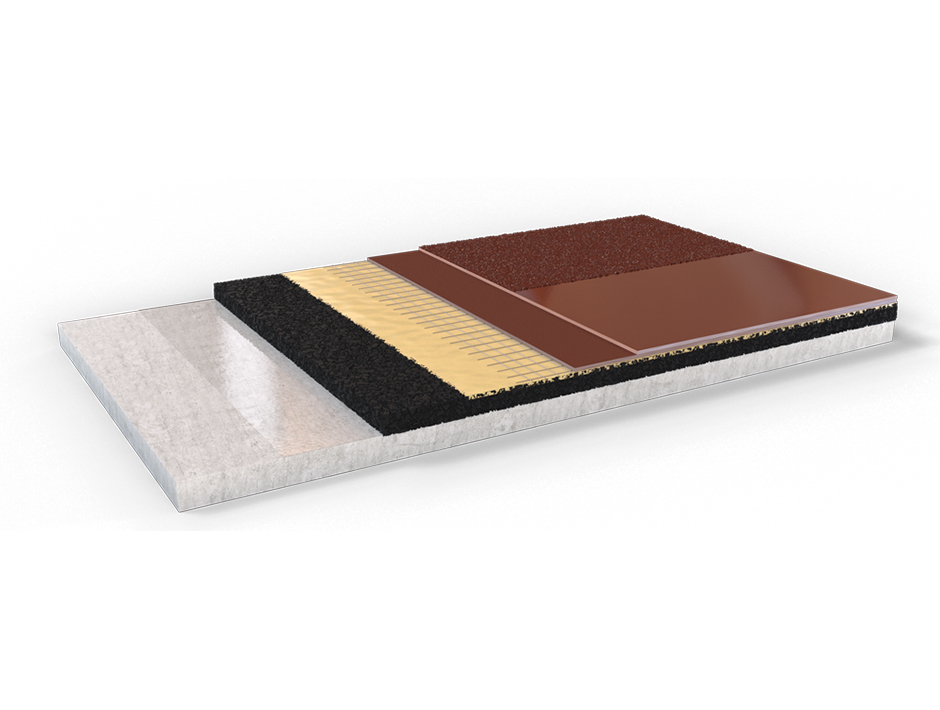

Synthetic, outdoor equine system in total thickness of 15mm up to 50 mm. It is applied on fine asphalt or smooth, waterproof concrete without rising humidity issues from the subfloor or from the sides of the concrete.

It consists of a first cushion layer (base layer) of 13-18mm usually, mixed and applied at site (consisting of RECYCLED RUBBER in different granulometries,1-3mm and 0,5-1,5mm and SBR dust as well and the polyurethane binder POLAPLAST P13) and then of as second layer (sealing layer) of polyurethane semi flexible pore-sealing material POLAPLAST P24 on top of the cushion mixture.

Then follows the third layer (surface layer) with the full-PU colored polyurethane self-leveling, semi-elastic POLAPLAST P25 and finally the top coating the UV-resistant polyurethane aliphatic coating POLYSPORT 1053 in two layers.

Priming with POLAPLAST P10 precedes all the application.

For anti-slip surface, after the application of the full-PU colored polyurethane self-leveling material POLAPLAST P24 follows broadcasting of quartz sand 0.1-0.4mm (3-4kg/m²). Then the surface is coated with the UV-resistant polyurethane aliphatic top coating POLYSPORT 1053.

Certified system by KIWA ISA Sport Institute.